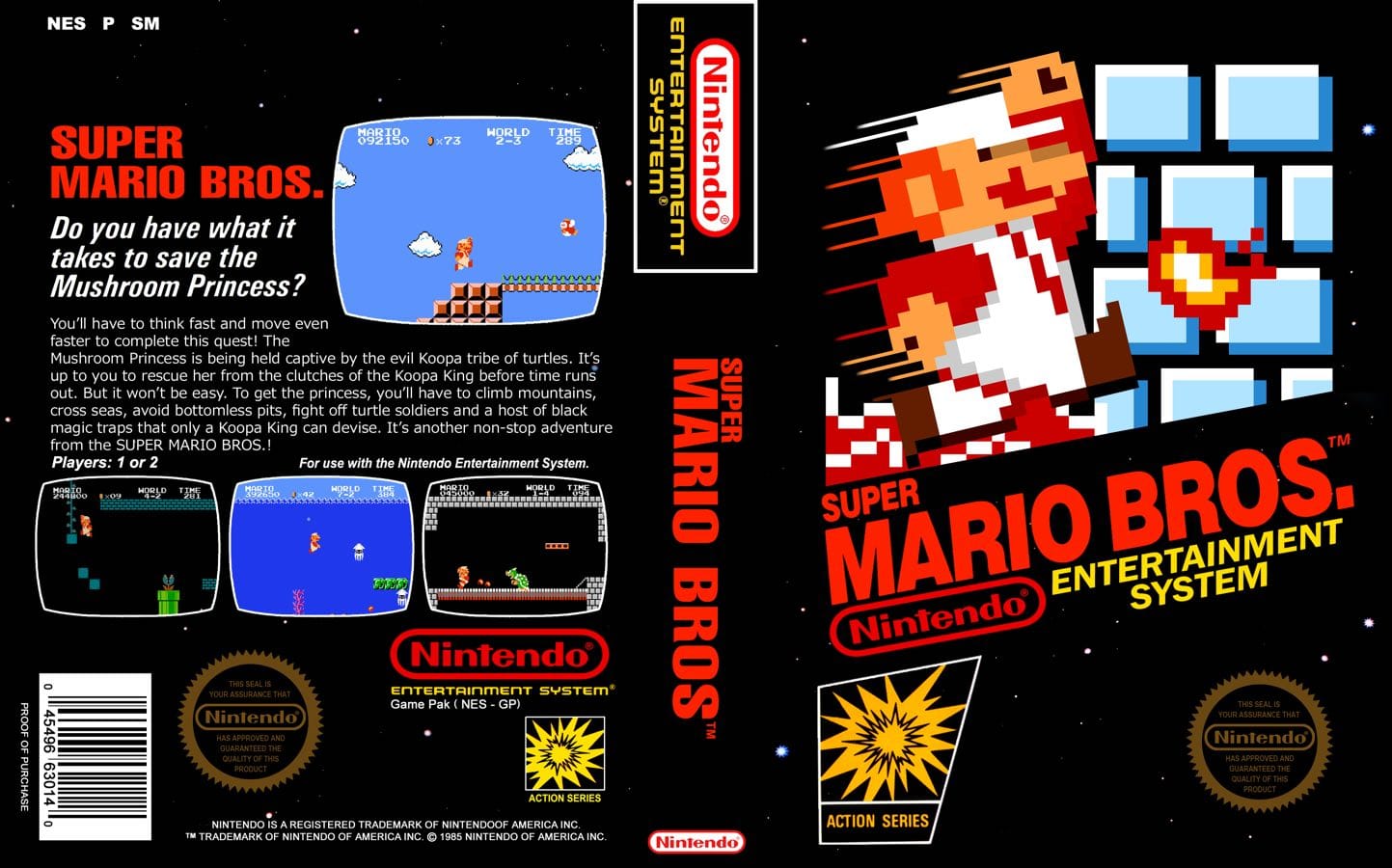

robot Made in a 3D printer I managed to win the first stage of the game “Super Mario Bros.” From nintendo. Well, the first stage of the game is one of the simplest in history, and you are practically born and know how to beat it, but continue with the story.

The project is part of the subdivision ofsoft robotsFrom the University of Maryland, USA, who are known for escaping traditional construction and foregoing solid materials to build their robots with flexible components, which mimic the physical properties found in animal tissues.

publicity celebrity

Read also

This is the case with the current project: Consisting of a three-fingered hand, the project is skilled enough to handle buttons and control the direction of the joystick. miscellaneous. The same team of scientists built two tortoise-shaped robots – the animal that represents the university’s mascot – and published their findings in a research paper from science progress.

According to the university, there are many advantages to using flexible materials: Imagine a robot whose entire body is so flexible that it digs into smaller holes, searching for victims of disasters such as landslides or earthquakes. Not to mention they can be used as prosthetics for lost limbs or for biomedical applications.

“Recently, several groups have attempted to perfect fluid circuits to improve the autonomy of soft-tissue robots,” said Robin Acevedo, a graduate student in Maryland and co-author of the paper. “But methods for building and integrating these circuits into robots can take days to weeks, with a significant amount of manual labor and technical capabilities.”

In 2016, scientists at Harvard University felt this in their skin, when developing an octopus robot and replacing hard plates with “microfluidic circuits.” These components regulate the flow of water (hydraulic) or air (pneumatic) rather than electricity, allowing the robot to move around and disorientate.

But this also entails difficulties: microfluidic circuits necessarily require sterile rooms; Its production time is longer and more expensive, and its integration into the automated system is more complicated.

Acevedo and his team have found a way around this with a technique known as “3D printing Polyjet,” which has a layer-by-microscopic resolution of 0.014 mm (mm) and is capable of producing thin walls and complex geometries using the widest range of materials available.

In other words: the printer adds one liquid layer, lets it dry, adds another layer, and it dries too, and so on.

“Incorporating materials that differ in hardness improves performance by allowing certain material properties to complement the job we desire,” said Ryan Sokol, co-author of the research. Elements such as the uterine diaphragm (l Contraceptive methods) or elastomer rings (used in some types of couplings and tubes), for example, need to be deformed into various shapes in order to accommodate changes in the body where they are placed, without losing efficiency.

In the case of the 3D-printed robot that embarrassed Super Mario, scientists created it with just a specific pressure point, which responded with different commands depending on the force exerted: a light touch that made the character move on the screen. The medium press causes a jump, and finally the strongest press corresponds to the letter buttons (B, A if not the famous “nintendinho” of its time).

Unlike other surveys of this kind, Acevedo and Sochol decided to socialize the designs of the bot that defeated Super Mario: “We share all of our designs for free, so anyone can download files, edit on demand, and 3D print — whether using their own device or with a third-party service. A third as we did – all the soft elements and the liquid circuits of our work.” According to Sochol, the cost of this type of production would be around $100 USD (519.86 BRL) with the software they used via GitHub.

“We hope this is open source strategy 3D printing expands accessibility, dissemination, repeatability, and adoption soft robots With fluidic integrated circuits, and over time, accelerating the advancement of the field,” Sokol said.

You have seen our new videos on Youtube? Subscribe to our channel!

“Coffee trailblazer. Social media ninja. Unapologetic web guru. Friendly music fan. Alcohol fanatic.”